QD4 SHELL-MITC element hyperboloid validation

This validation aims at assessing the behavior of the SesamX QD4 SHELL-MITC element (MITC4 element) against the equivalent Abaqus S4 element. We expect to notice some discrepancies between these elements because their formulation are different.

Validation model

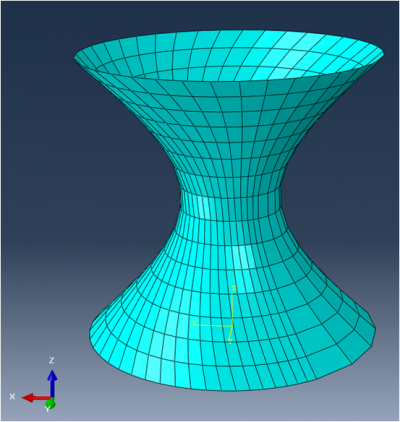

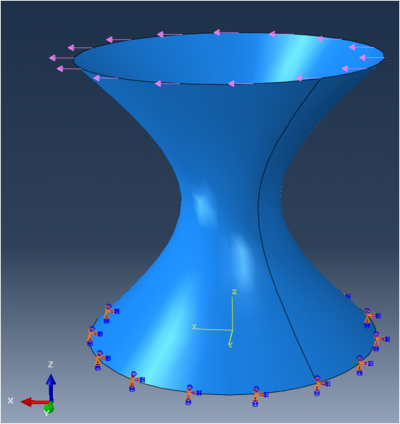

An hyperboloid-like model is studied for this comparison.

The mesh is voluntarily distorted and curved (the quads are not planar) in order to assess the robustness of the element. The bottom nodes circle are clamped while a uniformly distributed load along the $x$ axis is applied at the top nodes circle. A thickness of $80 mm$ is applied on the shell elements. A linear elastic material is applied with $E = 200 GPa$ and $\nu = 0.33$.

This case is solved as a linear static resolution.

Validation results

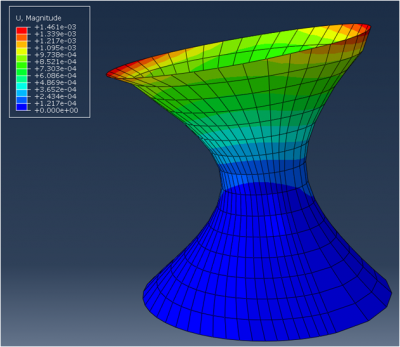

The following figure gives an overview of the hyperboloid displacement.

The following table gives the comparison of the nodal translations between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Node id | $u_x (m)$ | $u_y (m)$ | $u_z (m)$ | Magnitude $(m)$ | $u_x (m)$ | $u_y (m)$ | $u_z (m)$ | Magnitude $(m)$ | Magnitude error |

| 1 | -3.14E-33 | -2.85E-32 | 2.12E-32 | 1.16E-03 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | - |

| 200 | -1.20E-05 | -1.56E-06 | -4.34E-05 | 4.50E-05 | -1.26E-05 | -2.14E-06 | -4.34E-05 | 4.52E-05 | 0.46% |

| 400 | 3.93E-04 | -4.62E-07 | -2.23E-04 | 4.52E-04 | 3.91E-04 | 1.63E-06 | -2.21E-04 | 4.49E-04 | -0.63% |

| 571 | 9.62E-04 | -8.92E-05 | 4.61E-04 | 1.07E-03 | 9.59E-04 | -7.95E-05 | 4.50E-04 | 1.06E-03 | -0.78% |

| 583 | 1.11E-03 | 1.65E-05 | -9.52E-04 | 1.46E-03 | 1.06E-03 | 1.44E-05 | -9.03E-04 | 1.39E-03 | -4.72% |

| 596 | 9.58E-04 | 8.20E-05 | 4.54E-04 | 1.06E-03 | 9.41E-04 | 5.78E-05 | 4.24E-04 | 1.03E-03 | -2.78% |

| 608 | 9.89E-04 | -1.02E-04 | 5.91E-04 | 1.16E-03 | 9.88E-04 | -9.68E-05 | 5.86E-04 | 1.15E-03 | -0.39% |

The maximum difference is 5%. The nodal translation are very close between Abaqus and SesamX.

The following table gives the comparison of the nodal rotations between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Node id | $r_x (rad)$ | $r_y (rad)$ | $r_z (rad)$ | Magnitude (rad) | $r_x (rad)$ | $r_y (rad)$ | $r_z (rad)$ | Magnitude $(rad)$ | Magnitude error |

| 1 | 9.44E-35 | 2.39E-35 | -2.98E-35 | 1.02E-34 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | - |

| 200 | 5.14E-06 | 9.55E-06 | -1.37E-06 | 1.09E-05 | 5.89E-06 | 9.61E-06 | -1.36E-06 | 1.14E-05 | 3.93% |

| 400 | 7.71E-06 | 5.61E-05 | 2.28E-06 | 5.67E-05 | 7.38E-06 | 5.63E-05 | 2.42E-06 | 5.68E-05 | 0.27% |

| 571 | 8.20E-05 | 1.11E-04 | 1.22E-05 | 1.39E-04 | 6.63E-05 | 1.04E-04 | 1.32E-05 | 1.24E-04 | -10.47% |

| 583 | -2.20E-05 | 2.92E-04 | 3.93E-06 | 2.93E-04 | -9.48E-06 | 2.08E-04 | -3.32E-06 | 2.09E-04 | -28.67% |

| 596 | -1.01E-04 | 1.17E-04 | -1.15E-05 | 1.55E-04 | -5.65E-05 | 9.39E-05 | -4.82E-06 | 1.10E-04 | -29.21% |

| 608 | 9.58E-05 | 1.33E-04 | 5.14E-06 | 1.64E-04 | 8.16E-05 | 1.28E-04 | 6.80E-06 | 1.52E-04 | -7.37% |

The maximum difference on the rotations is 30%. The differences on the rotations are larger than on the translations. But we must be cautious about these results. Indeed, the Abaqus S4 element seems to have 6 degrees of freedom per node, while the MITC4 element implemented in SesamX has only 5 (no drilling rotation). Hence the S4 adds inevitably some terms on the rotational degrees of freedom.

The following table gives the comparison of the principal strains on the shell top surface between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | ||||

|---|---|---|---|---|---|---|

| Element id | $\varepsilon_{11} (\%)$ | $\varepsilon_{22} (\%)$ | $\varepsilon_{11} (\%)$ | $\varepsilon_{22} (\%)$ | $\varepsilon_{11}$ error | $\varepsilon_{22}$ error |

| 244 | -2.75E-04 | -8.60E-04 | -2.71E-04 | -8.69E-04 | -1.55% | 1.07% |

| 261 | 8.33E-04 | 2.59E-04 | 8.34E-04 | 2.54E-04 | 0.09% | -2.10% |

The following table gives the comparison of the principal strains on the shell bottom surface between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | ||||

|---|---|---|---|---|---|---|

| Element id | $\varepsilon_{11} (\%)$ | $\varepsilon_{22} (\%)$ | $\varepsilon_{11} (\%)$ | $\varepsilon_{22} (\%)$ | $\varepsilon_{11}$ error | $\varepsilon_{22}$ error |

| 244 | -2.81E-04 | -9.11E-04 | -2.76E-04 | -9.19E-04 | -1.80% | 0.96% |

| 261 | 8.77E-04 | 2.59E-04 | 8.77E-04 | 2.54E-04 | 0.03% | -1.77% |

The maximum difference is 3%. The strain values are close between Abaqus and SesamX.

The following table gives the comparison of the principal stresses on the shell top surface between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | ||||

|---|---|---|---|---|---|---|

| Element id | $\sigma_{11} (MPa)$ | $\sigma_{22} (MPa)$ | $\sigma_{11} (MPa)$ | $\sigma_{22} (MPa)$ | $\sigma_{11}$ error | $\sigma_{22}$ error |

| 244 | -1.25E+00 | -2.13E+00 | -1.25E+00 | -2.15E+00 | -0.28% | 0.81% |

| 261 | 2.06E+00 | 1.20E+00 | 2.06E+00 | 1.19E+00 | -0.12% | -0.99% |

The following table gives the comparison of the principal stresses on the shell bottom surface between Abaqus and SesamX.

| Abaqus | SesamX | Comparison | ||||

|---|---|---|---|---|---|---|

| Element id | $\sigma_{11} (MPa)$ | $\sigma_{22} (MPa)$ | $\sigma_{11} (MPa)$ | $\sigma_{22} (MPa)$ | $\sigma_{11}$ error | $\sigma_{22}$ error |

| 244 | -1.31E+00 | -2.25E+00 | -1.30E+00 | -2.27E+00 | -0.44% | 0.69% |

| 261 | 2.16E+00 | 1.23E+00 | 2.16E+00 | 1.22E+00 | -0.13% | -0.85% |

The maximum difference is 1%. The stress values are close between Abaqus and SesamX.

As expected, due to different element formulations, we notice a slight discrepancy between the Abaqus S4 element and the SesamX QD4 SHELL-MITC element. Besides, the mesh studied for this validation is quite poor but was chosen precisely to amplify any difference that may appear. As mentioned in our blog article about the shell element formulation, the SesamX QD4 SHELL-MITC element (MITC4) has been proven to behave better than the Abaqus S4 element.